250ML 330ml 1000ml Brick Shape Carton Filling Machine

1.Machine features:

1: Automatic feeding, sterilization, box making, filling, forming and sealing functions are completed in one time. The composite material is sprayed with hydrogen peroxide and high-intensity ultraviolet radiation and dried by aseptic hot air. The forming of the packaging box, the filling of the material Filling and filling of the closures are done in a sterile room with positive pressure to ensure aseptic packaging materials and equipment so packaged UHT-sterilized fruit drinks shelf-life of up to one year at room temperature:

2 The machine's PLC, photoelectric correction, frequency control. Pneumatic, solenoid valve, vacuum system, liquid level control, intelligent electronic temperature control. Automatic fault alarm system. Sterile room Dengjun Germany, Japan and other countries with well-known brands The whole machine is made of stainless steel, the appearance of beautiful, easy to operate.using quality weighing system control, quantitative filling, filling more accurate;

3. The use of mirror welding technology to ensure smooth weld formation, leaving no health corner;

4. Product valves and filling head moving parts using steam barrier protection, filling room with steam sterilization;

5. Using programmable logic controller for automatic device operation

6.Product warranty period: Using paper based composite packaging material, the shelf life is 12 months at room temperature of 25 to 30 degrees.

7.Suitable for packing material:

Polyethylene / paper (cardboard) / polyethylene / aluminum foil / polyethylene / polyethylene six layer web base composites.

Technical parameters

1)Capacity:800-1200 boxs/H

2)Sealing:By high frequency

3)Power:6KW 380V 50Hz

4)Weight:1000KG

5)Packaging material: roof cardboard box or roof aluminium foil cartonWith caps.

6)Shape size: 3.5*1.3*2.6 M

7)Compressed air: flow rate: 0.8-1.0M3/min

Pressure: 0.6-0.8Mpa No oil, no dust

8)Filling Type:Atmospheric pressure filling

9) Filling temperature:2-50° 80-88°

10)Filling Range: 250ML-2000ML

11)Filling error:±0.5ml

12)Air Consumption:80L/min

13)Installation request:Cement,floor tiles and plastic floors can be used,not need the corners.

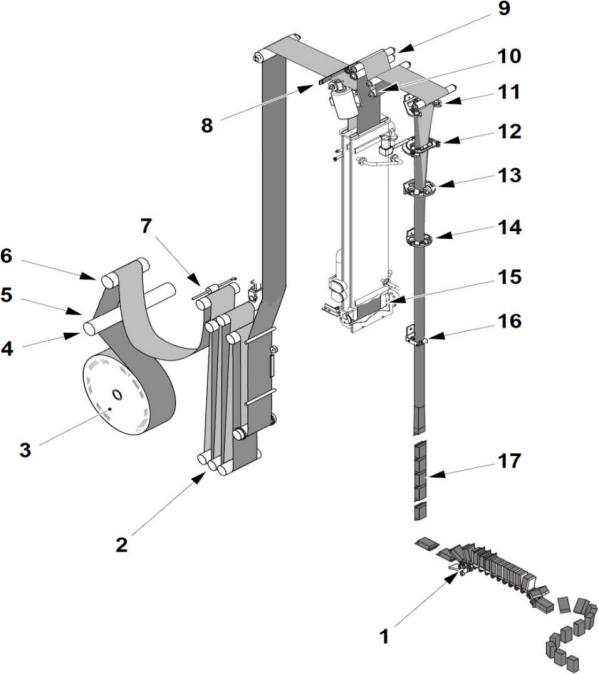

Molding diagram for packaging

|

1. |

Station chain terminal forming |

|

2 |

Storage of paper |

|

3 |

Package roll |

|

4 |

Splicing support shaft |

|

5 |

Automatic splicing device |

|

6 |

Guide roller |

|

7 |

Paper warehouse driver |

|

8 |

Entrance of sterile warehouse |

|

9 |

Squeeze the roller |

|

10 |

Floating roller |

|

11 |

Upper forming ring |

|

12 |

Movable ring |

|

13 |

Positioning ring |

|

14 |

Underform ring |

|

15 |

Double oxygen tank roller |

|

16 |

Paper tube support ring |

|

17 |

Grip the inner packing |

- Company Name:ANHUI KOYO BEVERAGE MACHINERY .CO.LTD

- Address:NO.669 WEST CHANGJIANG ROAD,HEFEI ANHUI CHINA

- Mobile(Whattsapp):+86-13856997681

- Telephone:+86(0551)-65692199

- Email:koyowater@gmail.com

- Fax:+86(0551)-65651988

English

English